Watchmaking & luxury

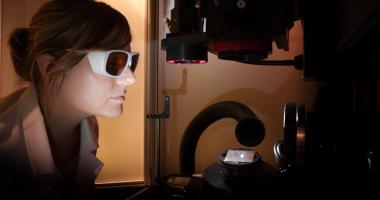

For over 10 years, ALPhANOV has acquired unique expertise in the development of precision machining laser processes in the watchmaking and luxury fields. To meet the challenge of obtaining a high degree of precision, ALPhANOV uses ultrafast lasers. These lasers allow us to bring essential qualities to the machining of watch parts. We are also able to support you in the implementation of R&D laser machining processes.

The characteristics of ultrafast lasers give them many qualities for micro-machining: flexibility in form and aspect, absence of contact, precision (from a millimetre to a micrometre), no damage to the material, limitation of the thermally affected zone, processes without post-treatment. These qualities are particularly useful for machining watch parts and, in the case of many processes, for: cutting, engraving, drilling, marking, surface texturing, intra-volume marking.

The applications are various:

- Engraving dials and bracelets

- Machining photos for the bottom of the dial

- Cutting needles

- Intra-volume marking in sapphire

- Micro-machining of pivots in ruby

This page shows you the services and products that we can produce for you.

Produits & Services

Publications

- Pulse to pulse control for highly precise and efficient micromachining with femtosecond lasers, G. Mincuzzi, E. Audouard, A. Bourtereau, M. Delaigue, M. Faucon, C. Hoenninger, K. Mishchik, A. Rebière, S. Sailer, A. Seweryn-Schnur, and R. Kling

- Beam engineering strategies reduce heat accumulation effects in high power, ultrashort pulse laser machining, G. Mincuzzi, A. Rebière, M. Faucon, A. Sikora, and R. Kling